Bioliff

Water . Tech

Bioliff

Water . Tech

Free

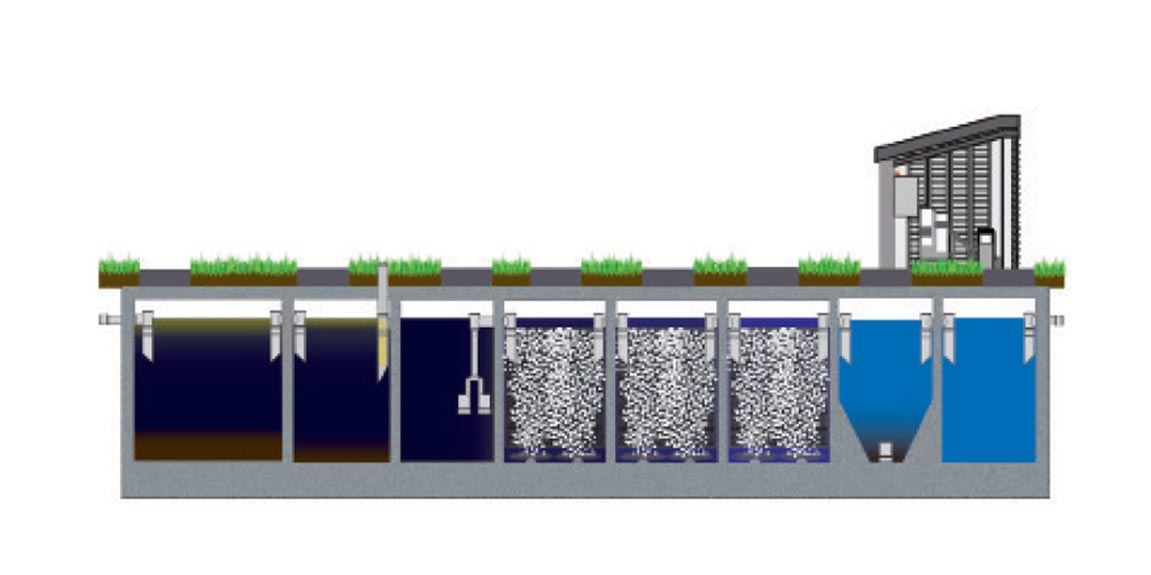

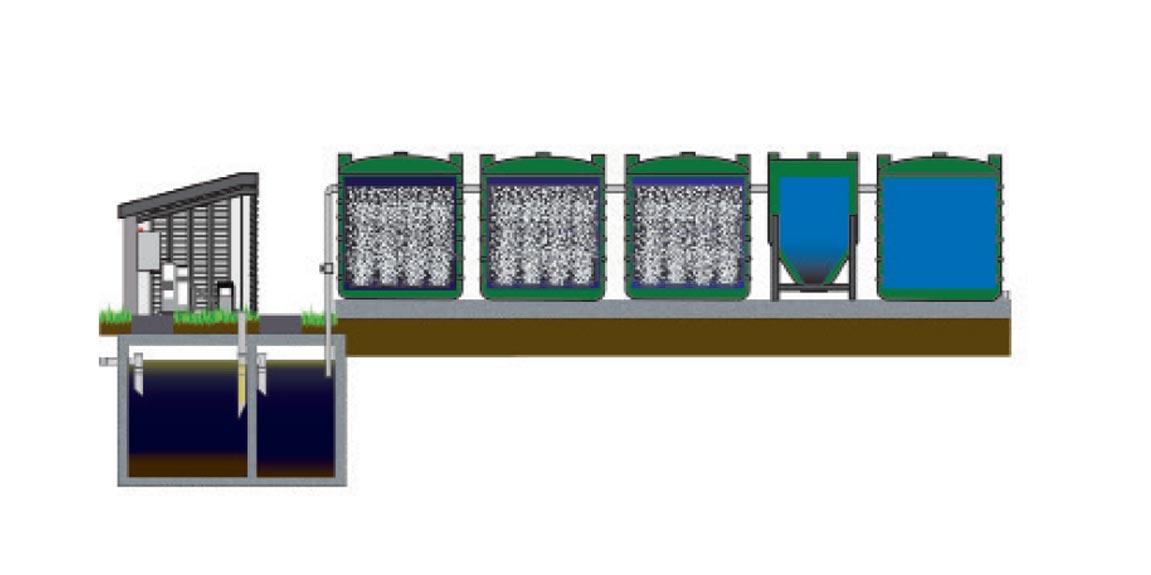

The Enpure wastewater treatment system is an advanced waste water purification technology designed to deliver effective sewage treatment forlarge communities. The process provides for full Carbon and Nitrogen removal to produce high quality effluent that is odour free, suitable for reuse such as in irrigation, outdoor washing and safe discharge into water courses. The treatment process is as below;

1. Primary Treatment: - The waste water, both black and grey enter the primary treatment chamber where some solids settle and the liquid effluent is passed through a brush filter to the second tank where more solids are filtered preventing passage to the reactors.

2. Buffer Tank: The buffer chamber regulates the amount of effluent that is fed into the reactor tanks. The plant runs at maximum efficiency when the effluent stream is at a steady, constant rate.

3. Aeration Reactor: The effluent enters the reaction chambers where countless bacteria lodged onto the fixed film media breakdown the waste in the presence of oxygen provided by an air blower. This fixed-film media is so designed to ensure that the system works even in the most difficult conditions of overloading, power cuts, downtime, flooding and toxic shock. It also ensures low sludge wastage reducing sludge removal to a minimum thereby saving costs.

4. Clarifier Tank: The effluent then passes to the clarifier tank where sludge settles at the bottom and clear water collects at the top.

5. Storage Tank: The final product, a clear, odorless and sanitized effluent is collected in this tank ready for discharge either by means of irrigation or onto natural watercourses.

Standard Enpure systems are for above ground installation using plastic poly tanks for each of the treatment stages. Alternative configurations for inground installation using a concrete structure or containerised for mobile systems are available.

Features include:-

BOD: 4mg/l, 99%

COD: 26mg/l, 96%

TSS: 3mg/l, 99%

*Testing done in conformity to EU Norm EN 12566-3, testing Institute: PIA in Aachen, Germany.

OPERATING CONDITIONS:

Medium: Organic waste not containing aggressive medium

Ambient Temperature: 250C

Medium Temperature: 250C

1. Primary Treatment: - The waste water, both black and grey enter the primary treatment chamber where some solids settle and the liquid effluent is passed through a brush filter to the second tank where more solids are filtered preventing passage to the reactors.

2. Buffer Tank: The buffer chamber regulates the amount of effluent that is fed into the reactor tanks. The plant runs at maximum efficiency when the effluent stream is at a steady, constant rate.

3. Aeration Reactor: The effluent enters the reaction chambers where countless bacteria lodged onto the fixed film media breakdown the waste in the presence of oxygen provided by an air blower. This fixed-film media is so designed to ensure that the system works even in the most difficult conditions of overloading, power cuts, downtime, flooding and toxic shock. It also ensures low sludge wastage reducing sludge removal to a minimum thereby saving costs.

4. Clarifier Tank: The effluent then passes to the clarifier tank where sludge settles at the bottom and clear water collects at the top.

5. Storage Tank: The final product, a clear, odorless and sanitized effluent is collected in this tank ready for discharge either by means of irrigation or onto natural watercourses.

Standard Enpure systems are for above ground installation using plastic poly tanks for each of the treatment stages. Alternative configurations for inground installation using a concrete structure or containerised for mobile systems are available.

Features include:-

- Reduced vibration and low noise due to the positive displacement blower at aeration chamber.

- Vertical configuration blower thereby saving space.

- Energy efficient over most conventional waste water treatment technologies.

- Modular design allowing for scaling up when higher capacity is required.

- The design and layout is flexible and can be suited to customer requirements.

BOD: 4mg/l, 99%

COD: 26mg/l, 96%

TSS: 3mg/l, 99%

*Testing done in conformity to EU Norm EN 12566-3, testing Institute: PIA in Aachen, Germany.

OPERATING CONDITIONS:

Medium: Organic waste not containing aggressive medium

Ambient Temperature: 250C

Medium Temperature: 250C

| Model | 50PE | 70PE | 100PE | 150PE | 200PE | 250PE | 350PE | 450PE | 500PE | 750PE |

| Population Equivalent (PE) | 75 | 75 | 150 | 150 | 200 | 250 | 350 | 450 | 500 | 750 |

| Flow, m3/day | 7.5 | 12 | 15 | 23 | 30 | 38 | 53 | 68 | 75 | 112 |

| Organic Loading (Kg/BOD/day) | 3 | 4.5 | 6 | 9 | 12 | 15 | 21 | 27 | 30 | 45 |

| Nitrogen Loading (Kg/NH/day) | 0.4 | 0.6 | 0.8 | 1.2 | 1.6 | 2 | 2.8 | 3.6 | 4 | 6 |

| Length, m | 4.5 | 5.5 | 7.5 | 7.5 | 7.5 | 9 | 10 | 12 | 12 | 15 |

| Width, m | 3.7 | 3.7 | 4.2 | 4.2 | 5 | 5 | 5.5 | 6.5 | 6.5 | 6.5 |

| Depth, m | 2 | 2 | 2 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 3 | 3 |

| Foot Print (m2) | 17 | 20 | 32 | 32 | 38 | 45 | 55 | 78 | 78 | 98 |

| Total Tank Volume (m2) | 33 | 40 | 63 | 79 | 94 | 112 | 138 | 195 | 234 | 293 |

| Installed Power, kW | 0.65 | 0.9 | 1.2 | 1.55 | 1.85 | 1.85 | 1.85 | 2.35 | 3.5 | 3.7 |