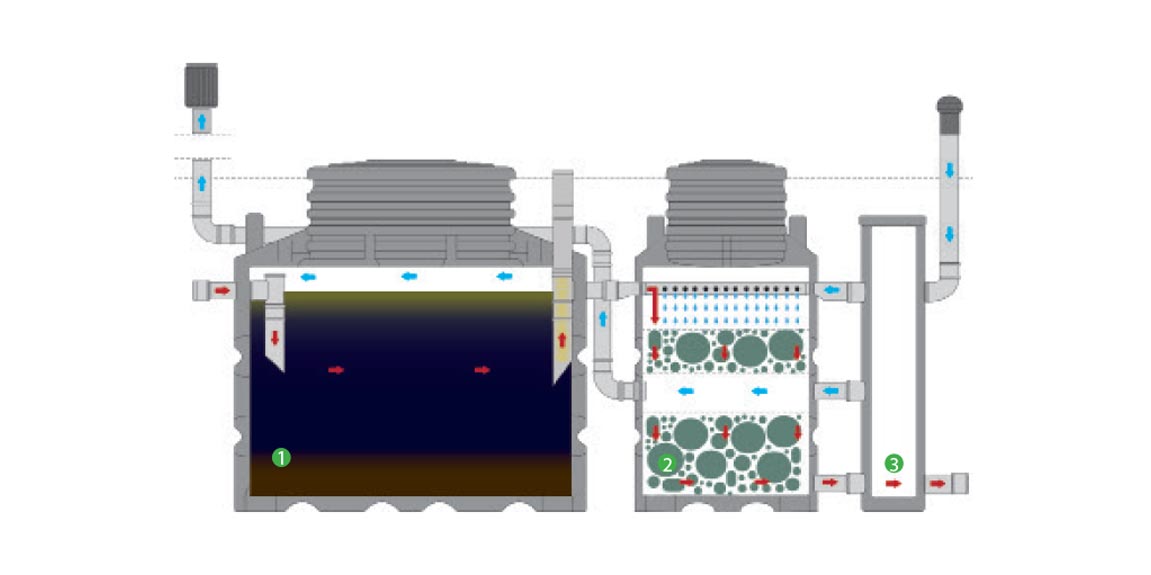

1. Primary Treatment: - The waste water, both black and grey enter the primary treatment chamber where some solids settle and the liquid effluent is passed through a brush filter to the second tank where more solids are filtered preventing passage to the reactors.

2. Buffer Tank: The buffer chamber regulates the amount of effluent that is fed into the reactor tanks. The plant runs at maximum efficiency when the effluent stream is at a steady, constant rate.

3. Aeration Reactor: The effluent enters the reaction chambers where countless bacteria lodged onto the fixed film media breakdown the waste in the presence of oxygen provided by an air blower. This fixed-film media is so designed to ensure that the system works even in the most difficult conditions of overloading, power cuts, downtime, flooding and toxic shock. It also ensures low sludge wastage reducing sludge removal to a minimum thereby saving costs.

4. Clarifier Tank: The effluent then passes to the clarifier tank where sludge settles at the bottom and clear water collects at the top.

5. Storage Tank: The final product, a clear, odorless and sanitized effluent is collected in this tank ready for discharge either by means of irrigation or onto natural watercourses.

Standard Enpure systems are for above ground installation using plastic poly tanks for each of the treatment stages. Alternative configurations for inground installation using a concrete structure or containerised for mobile systems are available.

Features include:-

- Reduced vibration and low noise due to the positive displacement blower at aeration chamber.

- Vertical configuration blower thereby saving space.

- Energy efficient over most conventional waste water treatment technologies.

- Modular design allowing for scaling up when higher capacity is required.

- The design and layout is flexible and can be suited to customer requirements.

BOD: 4mg/l, 99%

COD: 26mg/l, 96%

TSS: 3mg/l, 99%

*Testing done in conformity to EU Norm EN 12566-3, testing Institute: PIA in Aachen, Germany.

OPERATING CONDITIONS:

Medium: Organic waste not containing aggressive medium

Ambient Temperature: 250C

Medium Temperature: 250C

| Model | 50PE | 70PE | 100PE | 150PE | 200PE | 250PE | 350PE | 450PE | 500PE | 750PE |

| Population Equivalent (PE) | 75 | 75 | 150 | 150 | 200 | 250 | 350 | 450 | 500 | 750 |

| Flow, m3/day | 7.5 | 12 | 15 | 23 | 30 | 38 | 53 | 68 | 75 | 112 |

| Organic Loading (Kg/BOD/day) | 3 | 4.5 | 6 | 9 | 12 | 15 | 21 | 27 | 30 | 45 |

| Nitrogen Loading (Kg/NH/day) | 0.4 | 0.6 | 0.8 | 1.2 | 1.6 | 2 | 2.8 | 3.6 | 4 | 6 |

| Length, m | 4.5 | 5.5 | 7.5 | 7.5 | 7.5 | 9 | 10 | 12 | 12 | 15 |

| Width, m | 3.7 | 3.7 | 4.2 | 4.2 | 5 | 5 | 5.5 | 6.5 | 6.5 | 6.5 |

| Depth, m | 2 | 2 | 2 | 2.5 | 2.5 | 2.5 | 2.5 | 2.5 | 3 | 3 |

| Foot Print (m2) | 17 | 20 | 32 | 32 | 38 | 45 | 55 | 78 | 78 | 98 |

| Total Tank Volume (m2) | 33 | 40 | 63 | 79 | 94 | 112 | 138 | 195 | 234 | 293 |

| Installed Power, kW | 0.65 | 0.9 | 1.2 | 1.55 | 1.85 | 1.85 | 1.85 | 2.35 | 3.5 | 3.7 |

Free

Free

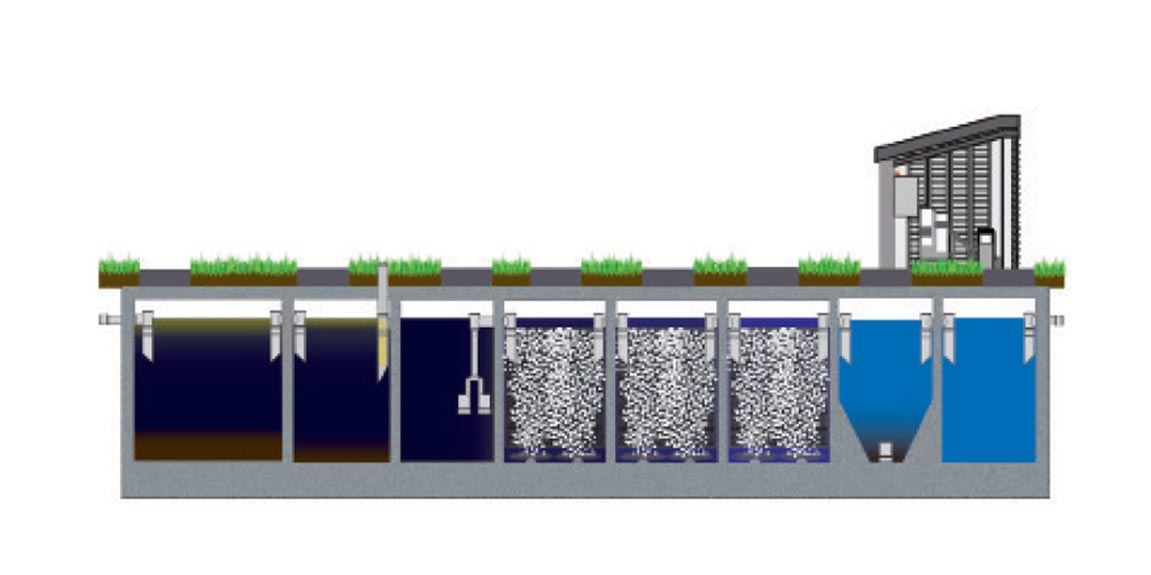

SBR systems use in-ground site constructed concrete chambers with ancillary equipment including aerators and pumps centrally installed and controlled in an adjacent machinery housing room. The purification process includes:-

Primary Treatment: Raw sewage and grey water is first processed in a two stage Primary Treatment chamber where liquids and solids are separated and some sedimentation takes place. The resultant settled fluid is then pumped to the main reactor tank in a batch of about 25% of daily treatment load.

Secondary Treatment: Secondary treatment occurs in a four phase process that includes aeration, biodegradrading and settlement, sludge settling to the bottom of the chamber while clarified water rises to the surface. This process takes about six hours after which the treated water is transferred to the final stage chamber and a new batch of raw water is introduced.

Storage: Chlorine dosage is introduced in the storage chamber after which the water is either utilised for irrigation, wash down etc or safely discharged to waste.

A feature of the design is an intelligent programmable controller that monitors chamber water level and controls the batch pumping and aeration without float switch control. Other functionalities including level alarms and plant malfunction are also included.

Reliable Pedrollo submersible sewage pumps are used for water transfer between cycles and aeration is provided by separate blower unit.

Bioliff SBR plants are of modular design and are specified according to particular population size, treatment requirements and site conditions, full details being provided for each installation.

| Model | 10PE | 20PE | 30PE | 50PE | 75PE | 100PE | 150PE | 200PE | 300PE | 500PE | 750PE |

| Population Equivalent (PE) | 10 | 20 | 30 | 50 | 75 | 100 | 150 | 200 | 300 | 500 | 750 |

| Flow (m3/day) | 1.5 | 3 | 4.5 | 7.5 | 12 | 15 | 23 | 30 | 45 | 75 | 112 |

| Organic Loading (kg/BOD/day) | 0.6 | 1.2 | 1.8 | 3 | 4.5 | 6 | 9 | 12 | 18 | 30 | 45 |

| Nitrogen Loading (kg/NH/day) | 0.08 | 0.16 | 0.24 | 0.4 | 0.6 | 0.8 | 1.2 | 1.6 | 2.4 | 4 | 6 |

| Length (m) | 2.0 | 3.9 | 4.5 | 6 | 6 | 6.5 | 8 | 7.5 | 14 | 10 | 13 |

| Width (m) | 1.8 | 2.6 | 3 | 4 | 3.5 | 4 | 5 | 4.7 | 3.7 | 7 | 7.5 |

| Depth (m) | 1.5 | 2 | 2 | 2.2 | 2 | 2 | 2 | 3.5 | 3.5 | 3.5 | 3.5 |

| Foot Print (m2) | 1.7 | 10 | 14 | 24 | 21 | 26 | 40 | 35 | 52 | 70 | 98 |

| Total Tank Volume (m3) | 5 | 20 | 27 | 53 | 42 | 52 | 80 | 123 | 181 | 245 | 341 |

| Installed Power (kWh/month) | 0.59 | 0.77 | 21 | 2.6 | 3.02 | 7.5 | |||||

*The design and layout is very flexible. For alternative layouts, smaller foot prints, or different depths please enquire.

**Due to the intelligent control panel and SBR cycle process the actual power consumption is much lower than the installed power would suggest e.g. 8PE SBR = estimate of less than 400kWh/year!Free

The two stage treatment process produces high quality effluent that may be discharged into sensitive watercourses. The biological process is simple and is gravity fed thereby ensuring reliability and low maintenance over traditional systems. The treatment process is as follows;

Stage 1

The raw sewage enters a primary tank where separation and breakdown of organic solids takes place.

Stage 2

The sewage then passes through an effluent filter before discharging into the ECOROCK® unit which incorporates ECOROCK media. This specially formulated media facilitates aerobic digestion and also contains microscopic pollution degradation bacteria preventing it from clogging. After digestion, a filtration process takes place before the effluent is discharged.

Features include;

- Works without electric power due to the design dispensing the need for pumps, blowers and compressors reducing lifetime costs.

- No moving parts resulting in no downtime due to breakdowns or wear and tear.

- Silent operation.

- Minimal maintenance.

- Ease of handling and installation eliminating need for concrete.

BOD: 4mg/l, 99%

COD: 26mg/l, 96%

TSS: 3mg/l, 99%

*Testing done in conformity to EU Norm EN 12566-3, testing Institute: PIA in Aachen, Germany.

OPERATING CONDITIONS:

Medium: Organic waste not containing aggressive medium

Max. Ambient Temperature: 400C

Max. Medium Temperature: 250C

| Model | ECOROCK 1500 | ECOROCK 3000 | ECOROCK 5000 | Multi-30 2XER5000 | Multi-60 2XER5000 | Multi-90 2XER5000 | Multi-120 4XER5000 |

| Population Equivalent (PE) | 6 | 18 | 30 | 36 | 60 | 90 | 120 |

| Flow, m3/day | 0.9 | 2.7 | 4.5 | 5.4 | 9 | 13.5 | 18 |

| Organic Loading (Kg/BOD/day) | 0.36 | 1.08 | 1.8 | 2.16 | 3.6 | 5.4 | 7.2 |

| Nitrogen Loading (Kg/NH/day) | 0.05 | 0.15 | 0.25 | 0.29 | 0.48 | 0.72 | 0.96 |

| Length, m | 1.15 | 2.15 | 4.5 | 2.15 | 4.5 | 4.5 | 4.5 |

| Width, m | 1.01 | 1.15 | 1.15 | 2.3 | 2.3 | 3.45 | 4.6 |

| Height, m | 2.1 | 2.1 | 2.1 | 2.1 | 2.1 | 2.1 | 2.1 |

Free

Free